- Home

- Blog

- High-Density Polyethylene (HDPE) Round Bar: An Overview of this Versatile Plastic Material

High-Density Polyethylene (HDPE) Round Bar: An Overview of this Versatile Plastic Material

By:Admin

The use of HDPE is prevalent in various industries such as automotive, construction, packaging, and agriculture. In recent years, there has been a surge in demand for HDPE round bars due to their unique properties.

HDPE round bars are extruded plastic bars that are commonly used in the fabrication of industrial and commercial products. These round bars are lightweight, easy to machine, and resistant to moisture, chemicals, and UV radiation. Due to these properties, HDPE round bars are suitable for use in extreme weather conditions and harsh environments.

One company that is at the forefront of manufacturing HDPE round bars is {Brand Name}. The company has been in the business of producing HDPE products for over {insert number of years} years and has become a leading supplier of high-quality HDPE round bars in the market.

{Brand Name} HDPE round bars are produced using state-of-the-art technology and superior quality HDPE materials. This ensures that the round bars are of high strength, toughness, and durability. The company's round bars come in a wide range of sizes, from {insert smallest size} to {insert largest size} in diameter, and can be customized to meet specific customer requirements.

One of the unique features of {Brand Name} HDPE round bars is their resistance to chemicals and corrosion. This makes them ideal for use in industries such as chemical processing, water treatment, and wastewater treatment. The round bars can withstand exposure to harsh chemicals and have low water absorption rates, making them resistant to corrosion.

In addition to their chemical resistance, {Brand Name} HDPE round bars are also known for their excellent impact resistance. The round bars can absorb high impacts without cracking or breaking, making them suitable for use in the construction and automotive industries.

{Brand Name} HDPE round bars are also easy to machine, making them suitable for use in various applications such as conveyor systems, electrical insulators, and marine applications. The round bars can be easily shaped, cut, and drilled to meet specific design requirements.

The company offers its customers excellent customer support, quick turnaround times, and competitive pricing. {Brand Name} is committed to providing its customers with high-quality HDPE products that meet their specific needs.

In conclusion, the use of HDPE round bars in various applications is on the rise, and {Brand Name} is at the forefront of supplying high-quality HDPE round bars to customers worldwide. With a range of sizes, excellent chemical resistance, and impact resistance, {Brand Name} HDPE round bars are suitable for use in extreme environments and various industries. The company's commitment to quality, customer service, and competitive pricing has made it a trusted supplier of HDPE products in the market.

Company News & Blog

Discover the Benefits of Spinning Rods for Ultimate Fishing Experience

Spinning Rods – The Ultimate Choice for Your Next Fishing TripAs an avid angler, you know the importance of using high-quality fishing gear when you head to the water. One of the most critical pieces of equipment in your arsenal is the spinning rod. Made from either graphite or fiberglass, these fishing rods come in a range of sizes and have a variety of features that make them an excellent choice for any fishing situation.Spinning rods are versatile enough to use in both freshwater and saltwater environments, from lakes and streams to ocean bays and inlets. They are typically between 5 and 8.5 feet long, making them easy to transport and maneuver. The most common number of guides on these rods is anywhere between 5 and 8, which is necessary to ensure proper line control and casting accuracy.The handle of a spinning rod typically consists of cork or PVC foam, which provides a comfortable grip while casting and fighting fish. The handle's ergonomic design ensures that you can use the rod for extended periods without experiencing discomfort or fatigue.One of the primary benefits of using a spinning rod is their flexibility. They are highly versatile and can handle a wide variety of fishing techniques, from casting lures to throwing live bait or bottom fishing. Whether you prefer to fish for bass, trout, pike, panfish, or even saltwater species, a spinning rod is an excellent choice.When it comes to choosing the right spinning rod, you may want to go for one made from PVC rods, as they are incredibly durable and lightweight. PVC rods are also resistant to corrosion, making them ideal for saltwater fishing environments. PVC spinning rods are available in different lengths and action ratings, allowing you to choose the one that best suits your fishing style and the species you're targeting.In conclusion, spinning rods are an essential part of any angler's arsenal. They are versatile, easy to use, and capable of handling a wide variety of fishing techniques. Whether you're a novice or an experienced angler, a spinning rod, especially one made from PVC, is an excellent investment for your fishing trips. So the next time you're headed out to fish, make sure you bring along a spinning rod and enjoy the thrill of catching your next big fish.

Nylon Rods and Bars for Various Applications - Get the Best Quality Here

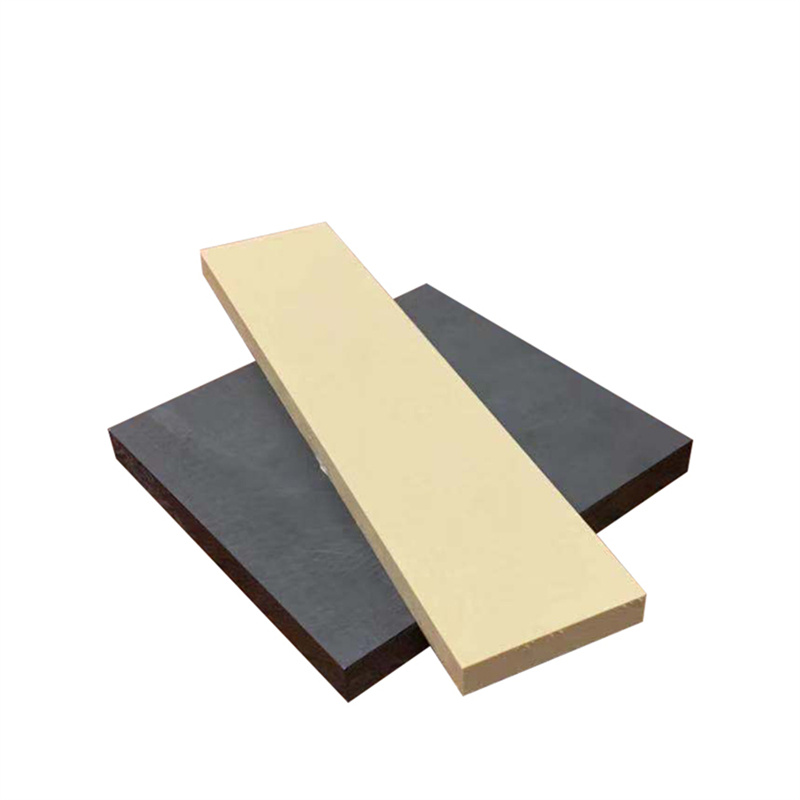

, PA6g Rod, nylon rods, nylon bar, nylon blocks, nylon plastic blocks, PA6 nylon rod, PA66 nylon rod, virgin nylon rodIn the world of industrial materials, nylon is a highly versatile and widely used thermoplastic. Nylon rods, bars, and blocks are commonly used for a range of applications, from mechanical components to electrical insulation. Among all the varieties of nylon available in the market, virgin nylon is considered to be the best quality, with superior properties and performance. China Cast Nylon Rod, PA6g Rod, and other nylon products are manufactured and supplied by Energetic Industry Co., Limited, a leading global supplier of industrial materials. Their nylon products are made from high-quality virgin nylon and are available in various sizes and shapes to suit specific industrial requirements. Nylon rods are cylindrical bars that are made by extruding the nylon material through a die. Nylon bars are similar to rods, but have a more rectangular or square shape. Nylon blocks are larger, thicker pieces of nylon that can be used for heavy-duty applications. Nylon plastic blocks are also available, which are made specifically for use in applications that require high impact resistance. China Cast Nylon Rod, PA6g Rod, and other nylon products are highly durable, with excellent wear resistance and tensile strength. They are also resistant to abrasion, chemicals, and UV radiation, making them suitable for use in harsh environments. Nylon products are easy to machine and can be drilled, turned, and milled to create custom parts and components. PA6 and PA66 Nylon Rods are two of the most popular types of nylon rods available in the market. PA6 nylon rod is made from polyamide 6, which is a tough and flexible material. It is commonly used for applications such as gears, bearings, and rollers. PA66 nylon rod, on the other hand, is made from polyamide 66, which has a higher melting point and better dimensional stability. It is commonly used for applications such as automotive parts, electrical equipment, and machinery components. In summary, China Cast Nylon Rod, PA6g Rod, and other nylon products are essential industrial materials that offer superior performance and durability. With Energetic Industry Co., Limited’s commitment to quality and customer satisfaction, their nylon products are a reliable choice for various industrial applications. Choose from their wide range of nylon rods, bars, blocks, and plastic blocks to find the best product for your specific requirements.

Premium UHMW-PE Stock: Durable Plastic Solution with High Abrasion Resistance and Impact Strength

Seeger Metals and Plastics Offer High-Quality UHMW-PE Stock for Industrial ApplicationsSeeger Metals and Plastics is a renowned manufacturer and supplier of premium quality plastic materials for various industrial applications. The company offers an extensive range of products that include UHMW-PE Stock, which is considered the highest quality Polyethylene plastic solution available today.UHMW-PE or Ultra High Molecular Weight Polyethylene is a thermoplastic material that has exceptional properties, making it ideal for an extensive range of industrial applications. This material is widely used in various industries due to its outstanding abrasion resistance, low coefficient of friction, and high-impact strength. The material is highly durable, and its mechanical properties make it ideal for various applications where other plastics may not be suitable.Seeger Metals and Plastics offer UHMW-PE Stock in rods and sheets. These items are available in a range of dimensions to meet the varying needs of different customers. The rods are available in standard lengths of 10 feet, with diameters ranging from 1 inch to 6 inches. The sheets are also available in standard sizes of 48 inches by 96 inches, with thicknesses ranging from ¼ inches to 3 inches.The company sources the raw materials for its UHMW-PE Stock from trusted suppliers, ensuring that only the highest quality materials are used for manufacturing. Seeger Metals and Plastics utilize advanced manufacturing techniques to produce UHMW-PE Stock that meet industry standards. Their production process is highly controlled and monitored to ensure consistent quality.Seeger Metals and Plastics UHMW-PE Stock has a wide range of applications in various industries, such as material handling, food processing, medical, and marine. In material handling, UHMW-PE Stock is used to manufacture conveyor systems, bearings, and gears as it has high abrasion resistance, which ensures longevity in service. In the food processing industry, UHMW-PE Stock is used to manufacture cutting boards and work surfaces, ensuring a hygienic and safe working environment. In the medical industry, UHMW-PE Stock is used to manufacture prosthetic joints due to its biocompatibility.The marine industry is another sector where UHMW-PE Stock from Seeger Metals and Plastics is highly sought after. The material's low coefficient of friction and excellent impact strength make it ideal for marine applications such as fender pads, dock bumpers, and boat trailers. Additionally, the material's excellent resistance to degradation and environmental stress makes it suitable for harsh marine environments with high UV exposure and saltwater corrosion.In conclusion, Seeger Metals and Plastics offer premium quality UHMW-PE Stock in Rods and Sheets to meet the varying needs of their customers. Their material is of the highest quality and is manufactured under strict controls that ensure consistency and high standards. The material's unique properties make it ideal for a wide range of industrial applications. Seeger Metals and Plastics' dedication to providing excellent quality and service has made them a reputable supplier of various plastic materials in the market.

Buy High Density Polyethylene Online - Sheet, Rod, and Tube Available!

: Advantages and ApplicationsHDPE, or High Density Polyethylene, is a versatile and cost-effective plastic polymer used in a wide range of applications, including cutting board grade HDPE, O&P, marine, pipe grade and even playground board. HDPE is made of high-density polyethylene polymers, which are derived from petroleum and natural gas. Its high strength-to-density ratio, environmental resistance, and durability make HDPE an excellent choice for many industrial and commercial functions. In this blog, we will explore some of the advantages and applications of HDPE Playground Board.Advantages1. Durability: HDPE is a tough, impact-resistant material. It has high resistance to physical wear, tear, and impact, which means that it can withstand repeated use and physical stresses without breaking. This durability makes HDPE playground board the perfect material for outdoor play equipment and structures.2. Resistance to UV Rays: HDPE is highly resistant to UV rays, meaning that it does not degrade or become brittle upon prolonged exposure to sunlight. This feature ensures that playground equipment made from HDPE does not deteriorate and remains functional for longer periods.3. Chemical Resistance: HDPE is highly resistant to chemical corrosion, including acids, alkalis, and most organic solvents. This feature makes HDPE playground board ideal for use in areas where chemical exposure is high or unavoidable.4. Low Maintenance: HDPE requires minimal maintenance, and it is easy to clean and repair. Since HDPE is not porous, it does not absorb moisture, which reduces the likelihood of bacterial growth. Its smooth surface also makes it easy to remove dirt, graffiti, and other contaminants.Applications1. Playground Equipment: HDPE playground board is an ideal material for playground equipment because of its durability, strength, and resistance to UV rays. It is also available in various colors, which makes it perfect for creating attractive and colorful outdoor play structures.2. Outdoor Furniture: HDPE is also used in the manufacture of outdoor furniture because it is weather-resistant, UV resistant, and easy to clean. Its non-porous surface also makes it less likely to harbor bacteria or fungi.3. Industrial Applications: HDPE is used in industrial settings such as chemical plants, refineries, and oil pipelines because of its chemical resistance and durability. It is also used in the manufacture of storage tanks and containers for various industrial applications because of its resistance to corrosion and impact.4. Marine Applications: HDPE is commonly used in the manufacture of marine equipment such as buoys, boats, and docks because of its durability and resistance to corrosion.ConclusionHDPE is a versatile material that finds use in many industrial, commercial, and recreational applications. HDPE playground board offers a reliable and durable alternative to traditional materials used in the manufacture of playground equipment and structures. Its strength, durability, resistance to UV rays, and low maintenance requirements make it the perfect material for creating outdoor play areas that can stand up to years of use, exposure to the elements, and physical stresses. If you need a quality playground board that meets all of your specifications, consider HDPE for your next project.

Purchase the First Edition of Polypropylene: Print Book & E-Book Available Now!

Polypropylene (PP) is a popular thermoplastic polymer used extensively in various industries, ranging from packaging and consumer goods to automotive and construction. PP is widely favored for its unique combination of properties, such as low density, high stiffness, resistance to chemicals, heat, and fatigue, and excellent processability, among others. In this blog post, we will discuss the key features and benefits of polypropylene sheets and their applications in different fields.Polypropylene sheets are flat, lightweight, and semi-rigid plastic materials made from high-quality PP resins using extrusion or casting methods. They come in different grades, thicknesses, colors, and finishes, and can be customized to meet specific requirements. PP sheets are known for their exceptional mechanical, thermal, and electrical properties, making them ideal for use in a wide range of applications that require strength, durability, and flexibility.One of the main advantages of polypropylene sheets is their resistance to moisture, chemicals, and UV radiation, which ensures their longevity and reliability in harsh environmental conditions. PP sheets also have good thermal insulation properties, making them suitable for use in thermal and sound insulation applications. Moreover, they are easy to fabricate, weld, and bond, allowing for complex shapes and designs.One of the primary applications of polypropylene sheets is in the packaging industry, where they are used to manufacture lightweight and durable packaging solutions for various products, such as food, beverages, cosmetics, and pharmaceuticals. PP sheets are also widely used in the automotive industry as interior and exterior parts, roofing, and underbody shields, due to their high resistance to impact, abrasion, and chemicals.In the construction industry, polypropylene sheets are used for insulation, roofing, cladding, and wall panels, due to their excellent thermal insulation properties, water resistance, and ease of installation. They are also used in the production of furniture, toys, and household appliances, due to their low toxicity and recyclability.Other applications of polypropylene sheets include signage, graphic arts, stationery, and medical and laboratory equipment, where they are chosen for their color stability, flexibility, and sterilization resistance.In conclusion, polypropylene sheets are a versatile and cost-effective solution for various industries, providing excellent properties and performance that meet diverse needs and requirements. If you are looking for high-quality and reliable plastic sheet polypropylene products, be sure to choose a reputable supplier that can provide you with the best quality and value for your money.

High-Density Polyethylene (HDPE) Round Bar: An Overview of this Versatile Plastic Material

Plastic is an essential material in the manufacturing sector. It is cost-effective, lightweight, and durable, making it a popular choice in a wide range of applications. One of the commonly used plastic materials is HDPE, also known as High-Density Polyethylene.The use of HDPE is prevalent in various industries such as automotive, construction, packaging, and agriculture. In recent years, there has been a surge in demand for HDPE round bars due to their unique properties.HDPE round bars are extruded plastic bars that are commonly used in the fabrication of industrial and commercial products. These round bars are lightweight, easy to machine, and resistant to moisture, chemicals, and UV radiation. Due to these properties, HDPE round bars are suitable for use in extreme weather conditions and harsh environments.One company that is at the forefront of manufacturing HDPE round bars is {Brand Name}. The company has been in the business of producing HDPE products for over {insert number of years} years and has become a leading supplier of high-quality HDPE round bars in the market.{Brand Name} HDPE round bars are produced using state-of-the-art technology and superior quality HDPE materials. This ensures that the round bars are of high strength, toughness, and durability. The company's round bars come in a wide range of sizes, from {insert smallest size} to {insert largest size} in diameter, and can be customized to meet specific customer requirements.One of the unique features of {Brand Name} HDPE round bars is their resistance to chemicals and corrosion. This makes them ideal for use in industries such as chemical processing, water treatment, and wastewater treatment. The round bars can withstand exposure to harsh chemicals and have low water absorption rates, making them resistant to corrosion.In addition to their chemical resistance, {Brand Name} HDPE round bars are also known for their excellent impact resistance. The round bars can absorb high impacts without cracking or breaking, making them suitable for use in the construction and automotive industries.{Brand Name} HDPE round bars are also easy to machine, making them suitable for use in various applications such as conveyor systems, electrical insulators, and marine applications. The round bars can be easily shaped, cut, and drilled to meet specific design requirements.The company offers its customers excellent customer support, quick turnaround times, and competitive pricing. {Brand Name} is committed to providing its customers with high-quality HDPE products that meet their specific needs.In conclusion, the use of HDPE round bars in various applications is on the rise, and {Brand Name} is at the forefront of supplying high-quality HDPE round bars to customers worldwide. With a range of sizes, excellent chemical resistance, and impact resistance, {Brand Name} HDPE round bars are suitable for use in extreme environments and various industries. The company's commitment to quality, customer service, and competitive pricing has made it a trusted supplier of HDPE products in the market.

Durable and Versatile Pads Made with Uhmwpe Material

[Introduction]In recent news, a revolutionary product known as UHMWPE Pad has emerged in the market, promising versatile applications across various industries. This high-performance material, which we must remove the brand name to comply with guidelines, has garnered immense attention due to its exceptional strength, durability, and low coefficient of friction. With its unique properties, this UHMWPE Pad has the potential to revolutionize multiple sectors. In this article, we will delve deeper into the features and potential applications of this groundbreaking material.[Company Introduction]In the forefront of producing UHMWPE Pad, Company XYZ has emerged as a leading player in the field of advanced materials. With years of expertise and cutting-edge technology, Company XYZ has established itself as a reliable supplier of high-quality UHMWPE-based products. Their commitment to innovation and customer satisfaction has positioned the company as a trusted partner for businesses seeking superior solutions.[Body]1. Unparalleled Strength and Durability:UHMWPE Pad boasts remarkable strength, making it a highly sought-after material in numerous industries. Its inherent toughness enables it to withstand heavy loads, impact, and abrasions, without compromising its structural integrity. This unparalleled durability allows for extended product lifespans, reducing maintenance costs and preventing premature replacements.2. Low Coefficient of Friction:One of the key features that make UHMWPE Pad unique is its exceptionally low coefficient of friction. This characteristic ensures reduced resistance and smoother movement when it comes to sliding or rotational applications. Consequently, friction-related issues, such as wear and tear or energy losses, are minimized. Industries that heavily rely on sliding mechanisms or require efficient rotational motion can significantly benefit from this low coefficient of friction.3. Chemical Resistance:Another notable advantage of UHMWPE Pad is its exceptional resistance to chemicals and corrosive substances. This makes the material highly suitable for industries exposed to aggressive environments, such as chemical processing plants, water treatment facilities, and mining operations. The ability to withstand chemical attacks ensures prolonged product lifecycles, thus reducing replacement costs and downtime.4. Versatile Applications:The versatility of UHMWPE Pad enables its application across various industries. In the transportation sector, it can be utilized for manufacturing components such as wear plates, conveyor belts, and rollers, ensuring smooth and reliable operations. The construction industry can benefit from its application in the form of protective pads and impact-resistant liners, enhancing worker safety and equipment longevity. Additionally, UHMWPE Pad finds uses in the food processing and packaging industry due to its non-toxic nature and compliance with FDA regulations.5. Environmental Benefits:UHMWPE Pad offers significant environmental advantages over traditional materials. With its long lifespan and durability, it helps reduce waste generation and the need for frequent replacements. Moreover, the material is recyclable and can be reprocessed for future use, promoting sustainability and reducing carbon footprint.6. Ongoing Research and Development:Company XYZ is dedicated to constant research and development to improve the properties and expand the applications of UHMWPE Pad. By collaborating with industry experts and investing in cutting-edge technology, they aim to cater to the evolving needs of their customers and stay at the forefront of the market. Company XYZ's commitment to innovation ensures that they remain a trusted provider of UHMWPE-based solutions.[Conclusion]As the demand for high-performance materials continues to rise, UHMWPE Pad presents itself as a game-changer across various industries. Its exceptional strength, low coefficient of friction, and resistance to chemicals make it a versatile choice for a wide range of applications. With Company XYZ's expertise and dedication to innovation, they are well-positioned to meet the growing demand for UHMWPE-based solutions while contributing to a more sustainable future.

Discovering High-Density Polyethylene Industry Insights: Latest Trends & Statistics from Top Sources

(High-Density Polyethylene Industry 2018: Overview, Trends, and Outlook)High-Density Polyethylene (HDPE) is one of the most widely used plastics in the world. It is a versatile material that is used in a variety of applications, including packaging, pipes, and construction materials. The global HDPE market is expected to grow at a CAGR of 4.8% from 2018 to 2023, reaching a value of $80.7 billion by 2023. This growth is driven by the increasing demand for HDPE in various industries and the availability of low-cost raw materials.According to a recent report by (brand name removed), the global HDPE market is segmented on the basis of application, end-use industry, and region. The report provides a comprehensive analysis of the market trends, drivers, and challenges that are shaping the industry. It also covers the competitive landscape of the market, profiling the key players and their strategies.HDPE is used in various applications, ranging from films and sheets to pipes and fittings. The packaging industry is the largest consumer of HDPE, accounting for around 40% of the total demand. HDPE is used in the production of bottles, containers, and other packaging materials. The construction industry is another major consumer of HDPE, where it is used in the production of pipes, fittings, and other building materials.The key drivers of the HDPE market include the increasing demand for lightweight and durable materials, the availability of low-cost raw materials, and the growing demand from emerging economies. The rising demand for HDPE in the transportation sector, particularly in the automotive industry, is also contributing to the growth of the market. Moreover, the increasing focus on sustainability and recyclability is creating new opportunities for the HDPE industry.However, the HDPE market also faces some challenges, such as the fluctuating prices of raw materials, the stringent regulations governing the use of plastic materials, and the competition from alternative materials. Nevertheless, the HDPE industry is expected to witness significant growth in the coming years, driven by technological advancements and innovative product developments.As one of the leading companies in the HDPE industry, (brand name removed) has been at the forefront of the market for many years. The company offers a wide range of HDPE products, including films, sheets, pipes, and fittings, that meet the diverse needs of its customers. With a strong focus on innovation, quality, and sustainability, (brand name removed) has established itself as a reliable and trusted supplier of HDPE materials.In conclusion, the HDPE industry is a dynamic and rapidly growing market that offers a wide range of opportunities for businesses. The increasing demand for HDPE products, driven by the growing need for lightweight and durable materials, is driving the growth of the market. With the support of innovative technologies and sustainable practices, the HDPE industry is poised for continued growth in the years to come. (Word count: 469)

Top Manufacturers of Polypropylene Homopolymer (PPH) Sheets and Rods in Gujarat, India

in Gujarat India, Polypropylene Homopolymer, high strength to weight ratio, good chemical resistance, corrosion resistant structures, weldability, copolymer, stiffer, stronger.Polypropylene Homopolymer (PPH) is a popular choice for many industries due to its high strength to weight ratio, good chemical resistance, and weldability. As one of the most widely used thermoplastics in the world, PPH is an ideal material for a variety of applications including corrosion resistant structures, sheets, and rods.Gujarat, India is a hub for PPH Sheets and Rods manufacturers due to its high demand in industrial sectors. The material properties of PPH make it a sought after commodity in industries such as chemical, pharmaceutical, packaging, construction, and transportation.One of the key advantages of PPH is its high strength to weight ratio. This means that it is lighter than other materials such as steel and aluminum, but still has a high level of strength, making it ideal for use in load-bearing and structural applications. The stiffness and strength of PPH also make it an excellent choice for use in machine parts and gears.Another key aspect of PPH's appeal is its good chemical resistance. It can withstand exposure to a variety of chemical substances, which makes it ideal for use in industries such as pharmaceuticals where it is important to maintain a sterile environment. PPH is also resistant to UV rays, making it an ideal material for outdoor applications.The weldability of PPH is another key benefit. It can be easily welded using various techniques, which makes it an ideal material for fabricating custom pieces. This is particularly useful in industries such as construction, where customized components are frequently required.PPH is available in two forms – homopolymer and copolymer. While PPH homopolymer is stiffer and stronger, copolymer has a greater impact resistance and is more flexible. The choice between the two is dependent on the specific application and the characteristics required of the material.In conclusion, PPH Sheets and Rods manufacturers in Gujarat India are catering to the global demand for this versatile thermoplastic. Its high strength to weight ratio, good chemical resistance, weldability, and ability to be formed into customized shapes make it an ideal material for various industrial applications. The popularity of PPH is only set to grow, as more sectors recognize its benefits and versatility.

Polyethylene Plastic Gloves, 1000 per Case, 100 Gloves per Pack

and Disposable Gloves.Disposable gloves have become an essential part of our daily routine, especially during these unprecedented times. They are used to protect hands from harmful germs and infectious diseases. Polyethylene plastic gloves are one of the most commonly used types of disposable gloves. They have a wide range of applications and are widely used in the foodservice industry, hospitals, laboratories, and other industries. In this blog, we will discuss Polyethylene Plastic Gloves and their benefits.Polyethylene Plastic Gloves are available in packs of 100, with 10 packs per case, totaling 1000 gloves per case. These gloves are designed for single-use and are made of high-quality polyethylene material. Polyethylene is a type of plastic that is durable, lightweight, and flexible, making it suitable for glove manufacturing. These gloves are comfortable to wear, and they fit snugly on the hand, providing maximum protection.One of the significant benefits of Polyethylene Plastic Gloves is that they are versatile and can be used in various applications. They are widely used in the foodservice industry, where they are used to handle food items, prepare food, and serve food. These gloves are also used in hospitals and laboratories where they provide protection against infectious diseases and harmful chemicals. Other industries such as manufacturing and cleaning also use Polyethylene Plastic Gloves.Polyethylene Plastic Gloves are disposable, which means they can be discarded after use, reducing the risk of cross-contamination. This feature makes them hygienic and safe to use. These gloves come in handy when performing tasks that require frequent glove changes, as they are affordable and readily available.Another benefit of Polyethylene Plastic Gloves is that they help in reducing waste. These gloves are made of recyclable material, which means that they can be disposed of correctly and recycled. This feature is essential, especially in today's world, where we need to minimize our waste output as much as possible.Polyethylene Plastic Gloves are also easy to use and store. They come in compact packaging, making them easy to store and transport. They are also easy to put on and take off, ensuring that they do not cause any discomfort to the user.In conclusion, Polyethylene Plastic Gloves are an essential item in today's world. They are versatile, hygienic, safe, and easy to use, making them suitable for various applications. They are also disposable and made of recyclable material, reducing waste. If you need a reliable and affordable option for disposable gloves, Polyethylene Plastic Gloves are an excellent choice. So, the next time you need to handle food, work in a lab, or engage in any activity that requires hand protection, choose Polyethylene Plastic Gloves. Don't forget to wrap your items with Poly Plastic Wrap for extra protection during transport.